So - here we go. No more excuses, time to put my skills to the test.

The transit time for my shipment was about two weeks from the time it left STW until it arrived at my door. During that time, I learned a few things about international freight forwarding, most importantly, YOU HAVE TO TRUST THE PROCESS.

In this time of Amazon - Same day delivery, and USPS daily updates on shipments in the mail, I have gotten used to clicking on a link and seeing where my package is. Well, you can not really do that in the world of international shipping.

MY SAGA

I got word from Rosalie at STW that my shipment had been picked up. Two days later I badgered the Freight Forwarder into telling me the expected flight date and Airlines/Flight Number. I hopped on the airlines website and only found part of my flights. The first one from the UK to USA (Dallas) was listed. The second flight from Dallas to Denver was not found. Since I was picturing in my head my pallet sitting in a warehouse in Dallas for the next millennium, I made a fool of myself and emailed the freight forwarder that there must have been a mistake. Well, DUH, I should have called the airlines, turns out the second "flight" was a TRUCK. Then I discovered that the Freight Forwarder in the UK turns the shipment over to another company that actually imports it into the US. They contact you when the shipment lands, and ask who your Customs Broker is. "What's a Customs Broker?" - They are responsible for talking US Customs and Border Protection into letting your shipment pass and stay in the US. Again - I had no clue, and asked the nice lady from the importer to recommend a Broker (she did and provided the paperwork). I never actually heard from the broker, I have not heard anything about paying them for their services, and since no one asked for any more money, I can only assume that there were no import duties on the shipment. Since the shipment was listed as "Model Steam Engine Parts" it appears that the US is not concerned. Finally, I heard from a local trucking company about delivery to my home, (took 3 days) the appointment was made and now I have my kits.

The most up-to-date information was from the American Airlines Cargo website. Once the shipment was in their hands it was tracked, but a lot of the status reporting was cryptic. I did have the option of Air vs Sea, but as screwed up as US ports are right now, there was no way I was going to let my toys sit in a container for a couple of months.

UN-PACKING

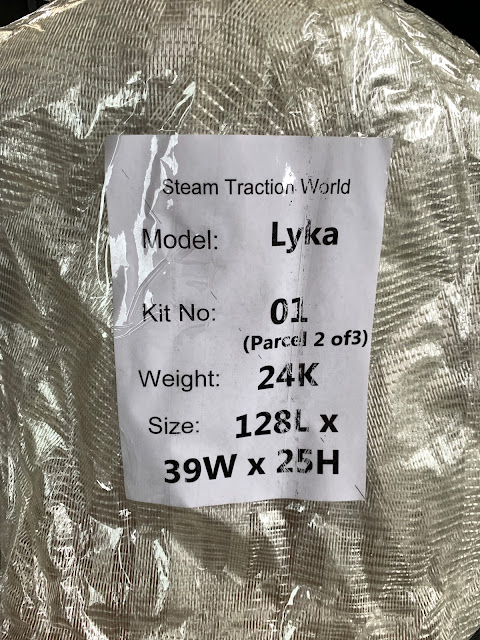

There was about a mile of shrink-wrap around the pallet, and it had been undisturbed during transit, so no close inspection (maybe they x-rayed it?). Once unwrapped, I found each kit, some in multiple boxes, to be labeled and securely taped, not with ordinary tape either, but hard-core strapping tape.

I opened each box, and cut off flaps. In some cases I cut the boxes down to about 1/2 height. The idea is to keep each kit intact until I need it. With the way the shipping department so expertly taped the boxes, they became very sturdy "trays" from which to work.

FITTING INTO MY WORKSPACE

I mentioned in an earlier post, that my allotted workshop space was 1/2 of a two car garage. So since I only had a 1-day "rental" of the other 1/2, I needed to fit the kits into safe storage during the build.

Luckily STW provided an excellent pallet for me to work with. Made of hard plastic, It was very sturdy and I was able to trim it down to 1/2 width. Then I put it on 4 - 3wheel castor bases, which gives me a way to move the pile around as needed.

In my workshop, I have a number of 4ft x 4ft "lifts", each with about 300lbs capacity. I had cleared one off in anticipation of this project, and used it to hold the tanks and the body frame parts which are some of the later kits. (also the most bulky for now).

END OF DAY 1

I could not resist the urge to put the chassis together and see if it would fit in my space. It is going to be tight, but doable. Specially when the wheels are on. Here is the chassis on the stands.

And finally, here is a view from the open garage door. The lift is up above the door. The pallet on casters is on the lower left. The large tool box on the left and the pallet can be moved. You can see another lift straight ahead that has a bunch of large clamps hanging from it. Thee is also a 2-ton hoist right above where the boiler would/will be.

So - tight but workable.

Now I need to haul dirt to pay my rent for the use of the other 1/2 of the garage. We are celebrating our 48th year this month, so it is not really a high price to pay given how much she puts up with when it comes to my "projects".

More to come - I will get a lot of pieces ready for the powder coater, so far I see nothing to concern me at all.

Regards,

Poppapope

1 comment:

Your workshop looks suspiciously like that of our father's. Glad to see the fire extinguisher is front and center. Looks very professional. I read all of this with interest and am very impressed. George put together the red jeep in the one-car garage we had at the time, and I never considered charging rent. Please thank Monica for the insightful idea. Dad had sent boxes, but most of it was together. This is amazing.

Anyway, I really enjoyed this. I hope I can find the updates; will you send an email? I'm really bad about these things. Thanks again and when is the anniversary? Ours is in two days. 42 years. Much love, V

Post a Comment

Thank you for posting your thoughts on my build.