Report from STW

I heard last week from Dean at Steam Traction World (STW). He is the Director or General Manager of the company. I suspect he is also the owner, but I do not know for sure. The UK has quite a number of different terms for everyday things.

Dean and I have corresponded and talked over the past two years during my association with STW. I have been somewhat frustrated over the extended time the production is taking and Dean wanted to set the record straight.

STW has been affected by the last 3 years in much the same way as other industries. Suppliers have been unable to meet schedules, a number of the foundries they deal with have closed, people retired or moved on, and production has suffered delays.

Dean has assured me that the Lykamobile production is getting back on track and he feels that the remaining kits will be produced by the end of the year. Over the past month I have seen reports and inventory lists for the various kits and I am feeling comfortable with the promise that my investment is not at risk. Which is good because I am not sure what I could do with a 1/2 a steam buggy.

Dean sent me some pictures of more boilers under construction. If this is all of the Lyka boilers, then it looks like there are 8 other Lyka projects out in the world and underway. It would be great to hear from the other builders and get to know them. So if anyone reading this blog is currently building a Lyka please let me know and we can compare notes as we finish over the next months.

Louvers

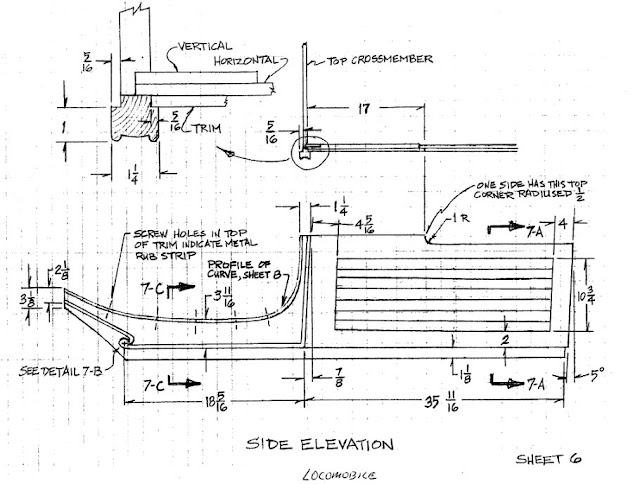

The original Locomobile had a body made of wood panels. Parts were made from or covered in leather, and the side panels on most models had strips of wood running horizontally on both sides. These strips resemble louvers but in fact are not functional. Grier, on his blog, showed that he had found a number of drawings relating to the features on the side panels for both Locomobile and also Mobile (offshoot of the original Loco) models of the time.

Using these drawings as a guide, I started looking for pieces of wood I could use as louvers. From what I could determine from previous STW production runs, the body panels are provided smooth so whatever additional features will have to be added by myself. I could not find the tear-drop shaped (side view) slats of wood already formed as louvers and I have limited wood shop tools. I decided to buy some slats that were already close in shape from our local wood-working store. Then I set up a sanding jig to allow me to get them into a shape closer to what we needed.

A little more clean up and I have a nice stack of "louvers." Now it came time to decide on the color scheme. I had already decided to accent my build with "British Racing Green" (BRG) and some of the engine parts have been painted that color. I started looking for additional sources for the color and find that there are a number of versions to BRG and so I stayed with type I used on the engine. This is actually Engine Paint that is high heat and has some ceramic of some type in it. It went on smoothly and too the gloss top coat very well. I will put it all aside until the body parts actually come in.

Well, that is about it for this week/month/quarter. First snowfall is supposed to happen this evening, I guess Fall and Winter are really here. I will have limited working time in the garage shop. Time to work on some of those in-side projects I have been putting off.

So - keep an eye out once a month or so just to see if I have gotten anything more from across the pond.

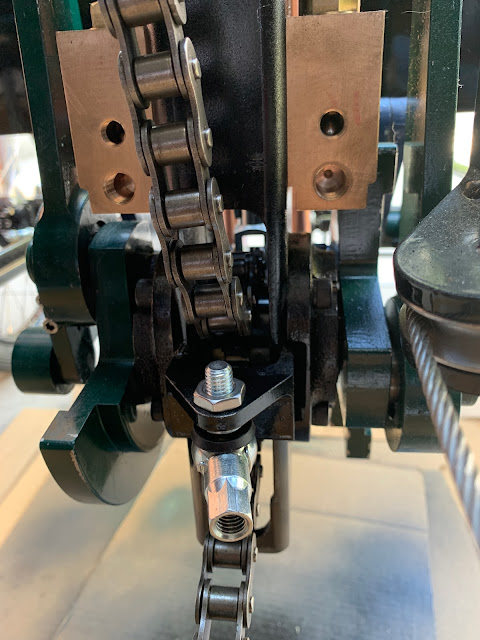

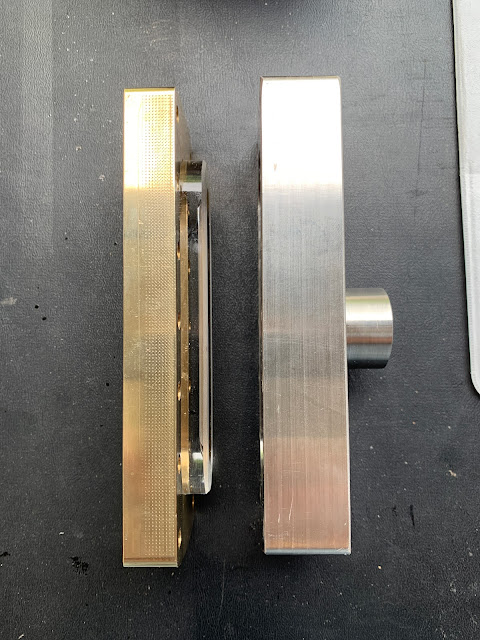

Here are some pictures of the Lyka as I get ready to store her for over the Winter.

Regards to all - Thanks for reading,