Boiler update -

I heard from Steam Traction World that the boiler design has finally been approved and the boilers were in production. It seems that since Brexit, there are now TWO agencies to make happy, one in the EU and one in the UK. They each have similar requirements, but must be dealt with separately.

Dean, the director of STW was kind enough to send me a picture of the boilers underway.

Hopefully, now that the details are worked out, the remaining kits can get organized and packaged without further delay. We have stalled waiting on the boilers with only piddling stuff to work on for the past year. It will be good to back on track.

Brake Light

During tests of the electronic package I designed, I discovered that the switch I had configured on the brake pedal was not going to work. The amount of movement required for switch contact was only about 1/8 inch. I am concerned that the vibrations in normal travel will result in false indications.

I found a more conventional brake switch that has a spring-loaded system where the contact is made after about 1/2 inch of travel.

The original attempt:

I removed that bracket and built a new one to hold the larger switch. The switch and bracket both have a little bit of "springiness" to allow the play in the pedal.

Playing with the Sight Glass Assembly

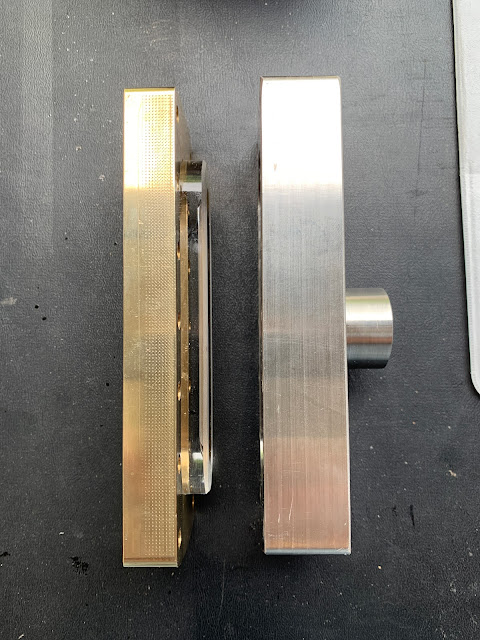

A part of Kit 18 was the Sight Glass Assembly. This consisted of two very hefty metal parts, one brass - one stainless, a glass lens, gaskets and a sensor system for the water level.

The hole in the back is for the sensor.

Steam Traction World had provided Black Oxide bolts, I replaced them with Stainless & Washers.

Water level sensing is done by using an IR (infrared) led and sensor. The prism lens changes how the light refracts when immersed in water. The change in levels is sent to the circuit box (in background) where it will open or close a relay (depending on the change) - if the relay is open, the flow of electricity to the burner relay is interrupted. This circuit is in series with two other control points, the pressure switch and the burner enable switch (on the dashboard).

The end result is three places that need to be in agreement in order to fire the boiler. I am also contemplating another level sensor, one that also had high and low points, in order to control the water bypass valve.

However - all of this goes in AFTER the boiler. So we will just have to keep on working on the little pieces that will help it go all together.

Thanks for reading,

2 comments:

Hi Jim,

I visited STW factory last week and was shown the Lyka boilers. I had a chat with the welder and guy who is making the boilers. Apparently one of the current issues is getting suitably certificated copper tubing for the 400 plus boiler tubes.

Hi Ian, Hopefully the proper tubing actually exists! I know that Dean was on vacation for the last 2 weeks, so now that he is back, things will continue to roll in the right direction.

Thanks for reading,

Jim

Post a Comment

Thank you for posting your thoughts on my build.