The Chain Drive

Kit 18 was a bit of a hodge-podge of parts and sub assemblies. There was the Wire Loom and Electronics, and the the Water Glass (which was just set in a box for when the piping actually showed up). Also in the kit was the Chain Drive and stiffener. Finally was the Steam Regulator, and cable assembly. Most of these pieces and parts were not usable until the Lyka was further along.

However, after sitting and looking at the big empty hole where the boiler and burner belonged, I decided to fit the chain, at least for now. I think this was a goo idea as it was a couple of links too long and required quite a bit of playing with. If I had waited until the boiler and burner were installed, I would have needed to work under the car on my back. As it was I could get everything fitted easily and can remove/replace it quickly when the boiler comes in.

Based upon Grier's experience I went to the McMaster-Carr website and ordered a 1/2 link of a 12B chain. This turned out to be necessary.

First step - Use a string to help pull the chain around the small-end engine sprocket.

Then loop the chain around the differential, and do a test fit for length.

A side view - pretty droopy.

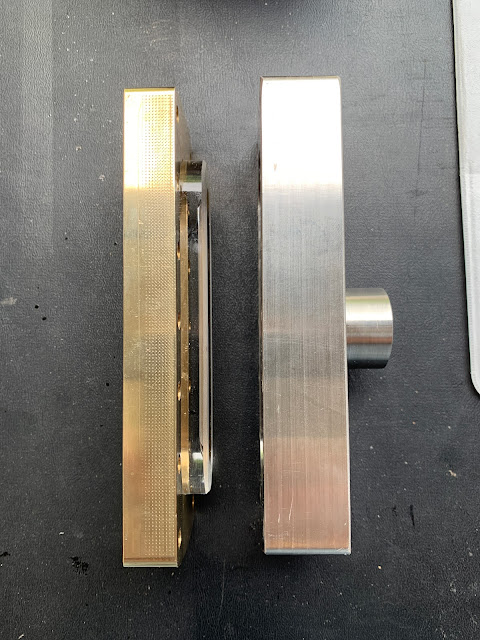

Here is the 1/2 Link along with the coupler provided by STW.

Here is the 1/2 link installed after removing the excess. You have to make sure you end up with the right parts next to each other.

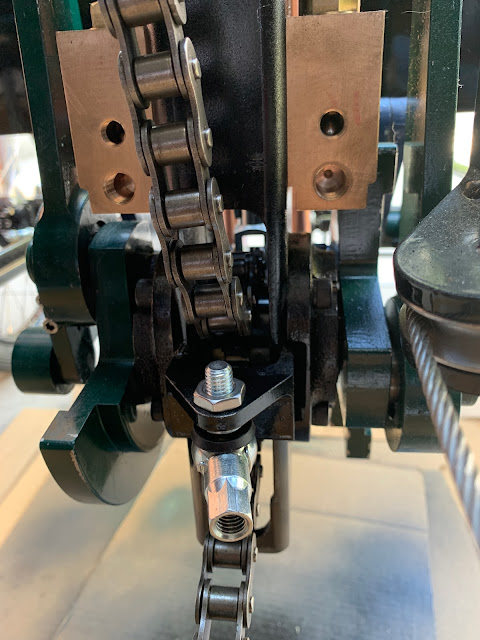

Chain Tension-er - There are two brackets that get a ball joint and then a tension rod is run between them. One ball joint fits to a small bracket in the engine mount tube that is in-between the chain runs. The mounting bolt must be ground down and a 1/2 thick nut used in order to avoid interfering with the chain travel.

After grinding down the excess bolt length and pulling the chain just tight enough, The droop is gone and the chain will clear the bolt.

So finally, the chain in place between the differential and the engine, checking the alignment. If I need to remove it to install the boiler and burner system, I will be able to hook it back up without a lot of crawling under the car.

Leaving it hooked up for now.

Thanks for reading,

Regards,