The journey so far - a recap.

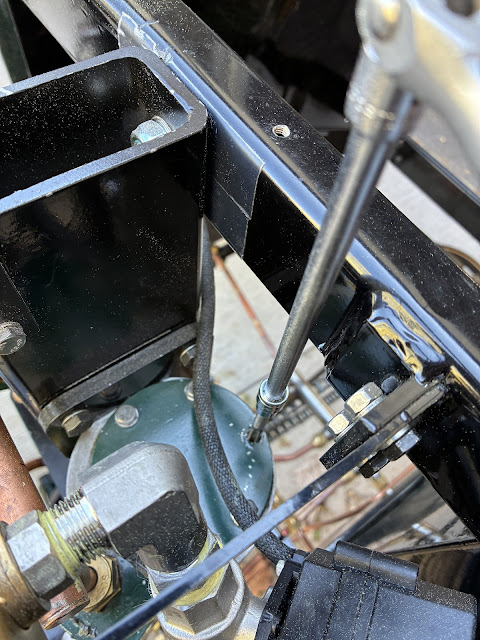

Here is a picture of my girl as she sits in my garage, today, May 24 2025, almost 3 years to the day from when I first fondled her frame.

Where am I now? Well I have received about all that I will be able to get from STW. I did some electrical engineering for them last fall when Dean was still in charge, and that has allowed me access to some details that might otherwise not be in the public domain. Also this relationship has allowed me to receive my boiler and about 80% of the remaining parts well in advance of other Lyka builders. (Sorry, not sorry). My boiler has been fully tested but it was not officially blessed by the BES. Since the USA does not give a rats ass about the BES, and there are no anal retentive inspectors looking over my shoulder, I asked to get my boiler NOW. STW obliged, and also picked as many of the available parts for kits 20, 21, & 22. What I was missing were some commercial items, like the pressure switch, safety blow-off valve, pressure gauge, the hand pump and a bunch of the copper pipes. I sourced all of the commercial items - mostly from McMaster Carr, Zoro, Steam Fittings UK, John Rex Engineering and Amazon. The remaining copper tubing I bought in bulk and learned how to do a "double flare".

For my fellow Lyka builders, I think there are about 9 of you, I will recap some of the things I encountered as I have gone thru the remaining process. A lot of this is covered in the individual posts so you can look there for more details. You should also study Grier's blog from the last build (2016). There is a link over in the right side column.

Since most of you are still waiting the boiler, I am assuming that you also are either waiting for or holding on:

Kit 15/16 Boiler

Kits 17a/b (flame shield, smoke hood, cladding,

Kit 19 - Some pipework, valves, inverter.

Kit 20 - Burner

Kit 21 - More pipes

Kit 22 - More (last of) pipes

During the last year you probably got:

Kit 18 - Wire loom, control box, regulator, chain. - Water Sensor (more on this).

Kit 23 - Body panels

Kit 24 - Seat

Kit 25 - Rest of Seat.

These 4 kits may be sitting in your "pile" at STW, in your garage waiting for action, or like mine - built, finished, enhanced and then stored until the rest comes in.

My build status:

I am waiting of a DHL shipment with 3 valve bodies from Kit 19 and a new inverter. Then I will be ready to begin pressure testing using water and air. Following that will be the burner install, adjustments and further testing. Then comes the first drive down the road.

Look to the next episodes for all of this.

If you have been following my posts to date, you know my background. While I am new to this size of steam vehicle, I am not inexperienced in steam in general, and I have build a lot of stuff over my 73 years on this planet. What I want to do with this post is catch you up on details covering the second 1/2 of the build.

General Observations - covering all kits.

The Lyka project lost it's champion after Steve died. Dean carried on with the help of Ian, but Ian retired in 2023. Since then Dean was pretty much doing what he could, but just did not live and breathe the Lyka. All the other engine products of STW are very well known to the staff, but not the Lyka. However, Dean was committed to all of us builders and I do not think our "investment" was ever at risk, even during/after Covid. What has further complicated things is that STW shuffled the kit contents a bit. So what was done in the 2016 build was not done in quite the same order in the 2022 build. Some of us like to "read ahead" and luckily Grier posted all the instructions from the 2016 build cycle. We just have to adjust for the shifting that has gone on.

If you have gotten thru Kit 14 (the engine) and maybe worked on the body panels, you should go over to Grier's blog and DOWNLOAD INSTRUCTIONS FOR KITS 15-23 (Boiler thru the last of the pipes) Note that Kit 23 (2016) included both body panels and pipework. Why do this - because STW has probably left out some details in the current instructions. It is possible that they may have corrected the information, but why take a chance?

Lastly, a word of advice, DO NOT Mount the sheet metal (Flame/Heat shield - bottom, Smoke Hood - top, Cladding/Smartwool) and Boiler UNTIL you have worked out all pipe runs. While the instructions allude to this, let me tell you that getting everything laid out, even if you take it off for a bit, is a LOT easier with out the boiler and the rest of the stuff in the middle.

Kit by Kit

Kit 15/16 boiler - It is a lump. A hernia just waiting to happen. Get a small "trolley" or "dolly" and use that for moving it around. But get some blocks of wood so you do not mess up the fittings you will insert into the bottom.

KIT17a/17b Heat shield, smoke hood, cladding - also has the fittings for the boiler mentioned above.

If your instructions do not have pages with a bunch of pictures (not ISOs) then download the instructions for Kit 18(2016) from Grier's blog and use those.

My Kit:

The bottom inside heat shield did not have the holes drilled for the standoffs. The plate for mounting the burner, the inner/outer shield did not quite line up. So I had to use longer screws and pull things into line. Some screws needed to be left out all together, and I just made sure that the smart wool was well placed.

SMARTWOOL is really a bitch to handle, first time my hands itched for a day. Wear gloves.

When you pre-stage the boiler - note that the ISOs and pics may not agree on the bottom right side blow-off connections - ISOs have a 2" nipple, Pics have two Ells - go with the pics- read the text. ALL CONNECTIONS - you will never see these again when they are assembled. STW has the habit of "tapping deep". so on all the connections to the boiler inside the shields, I used X-Pando. it is a steamseal on steroids. AND CRANK IT DOWN - ONE MORE REVOLUTION THEN YOU THINK YOU CAN DO!!!

On the top connections, after doing a dry-fit, and marking where the pieces need to go along the side of the boiler in order fit smoke hood, then mount everything BUT the center (main) output. See my post about the boiler. Once you install the boiler - you can put in the main outlet - but look for the Ell at edge of the boiler, you will need to heavily modify the upper/outer smoke hood to get that to fit.

AT THIS POINT STORE THE HEAT SHIELD/BOILER/CLADDING.

KIT18 - The water sensor. In the original Kit 18 there was a water level sensor that included a modification of the back 1/2 of the reflex glass. Ian (retired) had created a method to watch the water and turn off the burner if it dropped too low. His design used a really nice optical unit that transmitted light (ir) thru the water and told a relay system in a small box that all was well. If the water level dropped, then the relay opened and the burner was cut off. The issue is that the sensor is plastic. if you blowdown thru the reflex glass, you melt it.

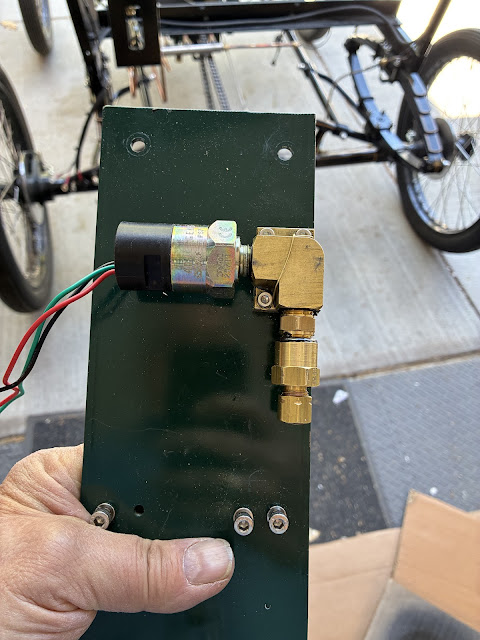

Dean commissioned me to expand on Ian's idea and create a sensor that would do the level determination electronically. There should be a second sensor kit somewhere in your shipment. I wrote an extensive manual to go with it. RTFM. If you do not find it, get with Production@ to request a kit be sent out.

Read my previous posting to see about the mounting of the box. I would wait until you finish the pipes to do so.

KIT19 - Drain down (blow off) valves, cylinder drains.

Make sure you actually have the valve bodies. My kit was marked complete, but the bodies were missing. If you have been sitting on the kit for a while, and you are missing the bodies, email Production@ rather than admin@ since Rosemary will just forward your issue anyway.

Install these up to the point where you would hook them to the boiler. See my posts about the steam chests.

KIT20 (Burner) - Very straight forward, although you can not do anything until the shield is in place.

You can drill the holes for the fuel filter bracket and make sure the copper tubing is run correctly. However, you will need to hold off on the actual filter until the boiler and the rest is in place.

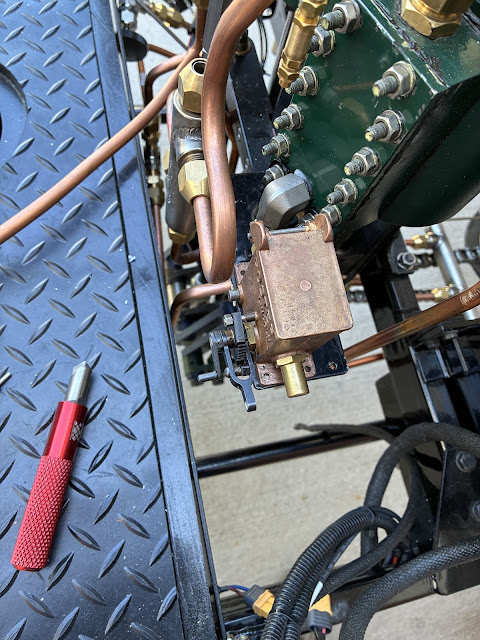

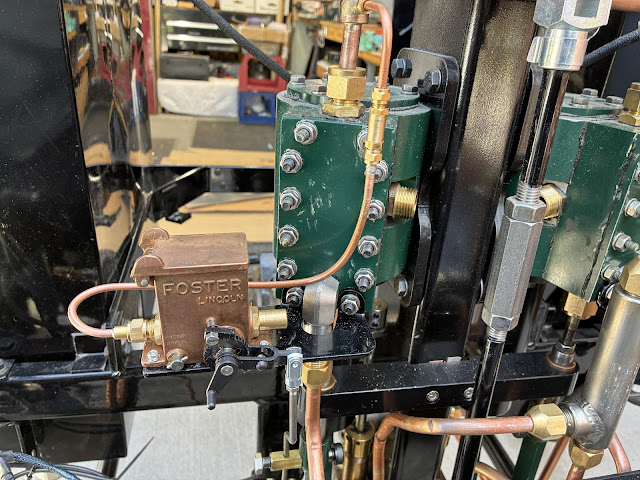

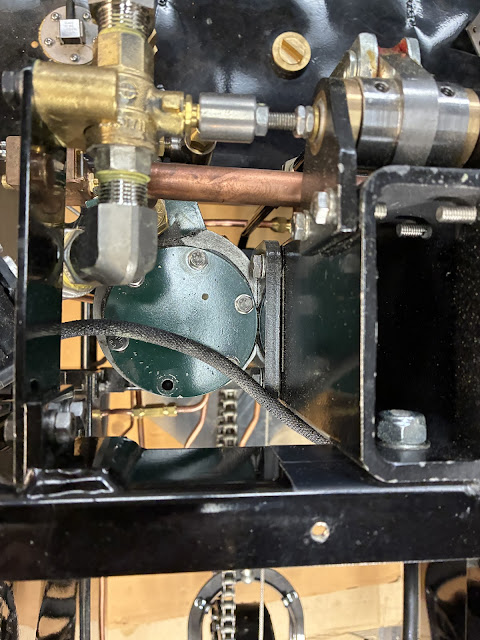

KITS21 and 22 - all the rest, water pump feedwater piping, steam outlet, regulator, pressure switch, etc.

This is the hard part - WAIT UNTIL YOU HAVE BOTH KITS. That way you can be sure you have everything and can stage it first.

I would suggest that you put the fittings on the water tanks, mount the tanks, do all the hookups where you can actually get to the piping as much as you can do. Then disconnect the flare connections at the tanks and pull the tanks - putting them aside for now. Leave the rest of the pipes in place, they will help hold up the heat shield later. Build the feedwater system including the hand pump and it's connections.

Run the small tubing for the pressure gauge/switch run and insulate any connection s you do not want to heat-up. When you have done as much as you can do, stage the steam outlet connections.

INSTALLING THE HEAT SHIELD AND BOILER

Contrary to the written instructions, insert the flame/heat shield FIRST. Put a piece of cardboard on top of all the pipes you have already installed. I used a floor jack to hold the shield up and engaged against the three support tabs. I had to cut a little of the shield at one of the notches in order get it to fit. Then you can lower the boiler into place and make sure to engage the two. Keep the jack in place and insert the stays. Remember that the stays in the rear positions need two nuts, one for the bracket, and one for the shield. The front stay may be too long. Cut it down to a more usable length. I had to use multiple extensions and come up from underneath with a deep socket in order to tighten it up.

Check out the previous posts for additional details.

In conclusion:

This series of Lyka kits may be the last for a while. STW is in a state of transition mixed with confusion. Dean was pushed out by his "partners" and it is up to the remaining production and office staff to make everything work. The people I have been working with are trying very hard to fulfill all of the kits for the various models they have been producing. I applaud their diligence.

I have a few more things to do before I start pressure testing.

More to come . . .

Thanks for reading.

Jim Pope

Denver, CO USA