Saturday - June 14 - A day that will live in infamy -

A view backwards a couple of days

OK, now that I have driven her around the neighborhood a couple of times, and before I button her up with side panels, I guess I should review some of the adaptations and adjustments I have made since the last episode.

The Basket

STW provides a basket to cover the burner. It is a bit oversized and will accommodate the burner in either orientation. The basket has an open "back" and is held to the rear body panel with 3 bolts and a flat bar across the top inside the lid. There are also some wedges to provide support on the sides as the back panel has a "slope" to it.

I have a mounted license plate lamp and plate holder so I needed to adjust the height to limit interference between the two. Once the wood wedges are mounted, you drill the three holes for the metal bar.

I used a jack stand to hold the basket in place for fitting.

Mark and drill the wedges, used the metal bar as a template to drill for the mounting bolts. I decided to make the bolts into studs by bringing them thru from the inside. I then put a lock nut on to secure the bolt in place and reduce the possibility of unscrewing them. Then I impaled the basket on the studs and drilled out the holes so the basket slid easily on and off.

You might notice that there is an opening facing forward next to the burner inside the basket. I am worried about the aspect of dropping things on the road as I tootle along. So I picked a piece of luan of the scrap pile and cut it to make a back "wall" that is held on by one of the bolts. Adding a piece of spare "Tupperware" gives a place for stuff to stay safe. I am thinking oil cans and "fast access" tools.

So here is the final result:

Exhaust Pipe

The exhaust pipe as issued by STW is a simple stainless steel "T". It sits on the top of the smoke shield and directs the hot air out each side. The issue with this is the it gets HOT. I have a few concerns, the first is burns - a casual arm draped over the back of the seat could easily come in contact with the pipe. Young children have curious fingers, and could easily get damaged. The second is that my trunk on the rear deck could be damaged by excessive heat.

I have some pipe insulation wrap the does a very good job of isolating heat from soft flesh. So I wrapped an initial layer and then soaked in it "water glass" which is a very good adhesive and withstands up to 2000 degrees.

This configuration still got hot, but did not blister the little fingers. When I finished assembling the boiler and burner system, I noticed that the heat output did cause the water tank filler cap to get too hot to handle, so I did some Amazon shopping and found a pair of "bullnose dryer vent deflectors". I cut these up and added additional wraps of the tape and coats of water glass. The result is a little bulky, but not overly so.

A good coating of black engine paint and we have a warm smokestack with the heat and smoke deflected upward. You still do not want to stand there and stare down in but the danger is past.

Oh Crap - Things fell off!

I drove her around the neighborhood a couple of times. I usually started off smoothly, but then within a block things got a little jerky and rough. Limped back home and put her up on stands. While trying to avoid burnt fingers, I studied the movement of the crankwebs. I found that the large counter-sunk flathead screw at the center of the crank shaft had started to work loose and was interfering with the movement by hitting adjacent pieces.

Here is the low-speed study of movement:

Quite disconcerting to say the least. When you look at the bolt, there is not much clearance nor is there easy access to the head so you can tighten it. I cut off about 3/4" of a 10mm allen wrench. Then I could fit this into the hole and turn it with a open end wrench. I am able to get it quite tight. So then I loosened it, and backed it out as far as I could get it. Then I squirted some red loctite in and torqued it back down.

After making sure each side was tight, I painted a "witness mark" on each to watch it in the future.

Went back out and down the street, came back home - still occasional clicks - checked the marks:

OK, What's going on? What could be causing the bolt to rotate? Looking at the build drawings, I see that the crack has a square head where it is attached to the crank web. The bolt is holding the web on the crank, but there should be no "radial" movement caused by the rotation of the crankshaft. So it has to be something hitting/rubbing the head during rotation that is moving it.

Doing further low-speed rotations shows that there are points where the linkages do not move smoothly, and there is noticeable in/out movement of the crank web - about 1/8". Look harder.

Then when I was cleaning up the driveway, I found this:

Where the hell did that come from? and Why? I do not remember grub screws. Where could that be from? Looked around for a couple of days and then I guess I put the screw down somewhere. Lost it.

But why are things dropping off? BECAUSE I FORGOT TO THREADLOCK THEM!!

Two years ago, when I was assembling the engine, the manual said - "do not threadlock yet until you have everything moving smoothly, but remember to do so afterward." Guess I forgot, huh?.

So now I went around the engine looking at the parts that should have been threadlocked. Well, I found the problem.

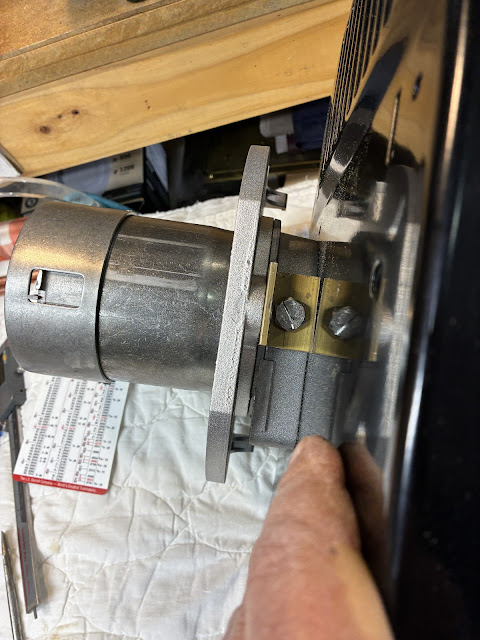

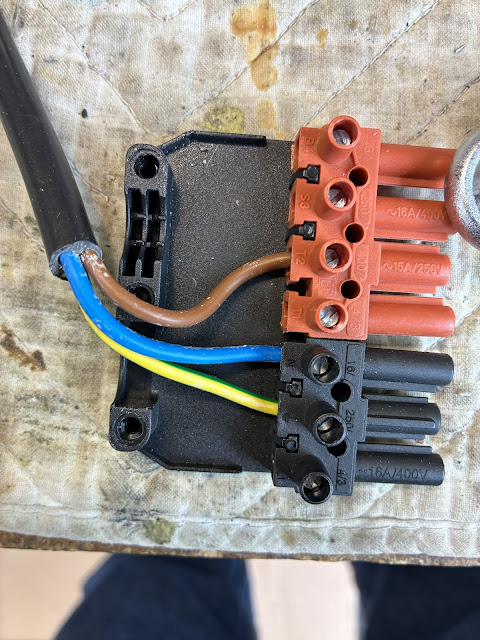

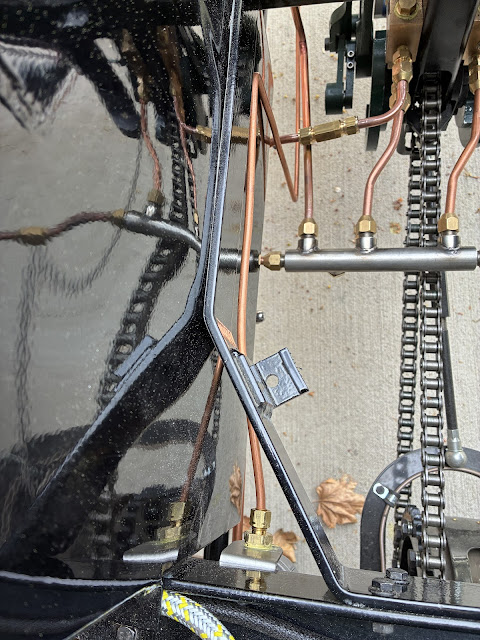

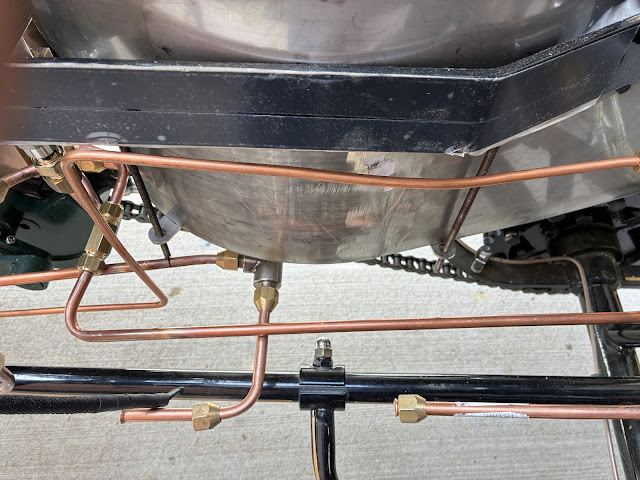

I lost two bolts off the crank bracket and the other two are loose. This allowed the whole bracket to shift sideways causing all the weirdness. You can see the impact of the crank on the brass water pump housing. Consulting the "miracle of Amazon" got me 10 - 8mm x 16mm stainless socket head bolts - overnight. Next day I went around and after using some brake cleaner and rag to clean out the holes, I did the threadlocking I should have done before, cranking everything down.

While I was under the car, I looked up and inspected the drive gear. Guess what - the missing grub screw mystery solved!! 1 missing - 2 loose - 1 still tight.

Now that I can not find the one I had, another amazon order. Once those come in and more threadlock applied, I will do some more test drives. I really want to get everything smooth before putting the sides back on.

Doing so will complete the look, but make getting into the engine compartment that much harder.

The next episode will cover the initial steaming experiences.